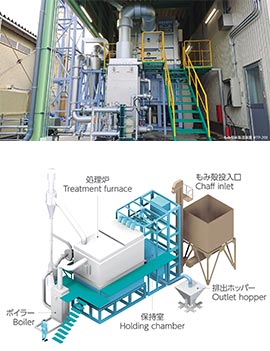

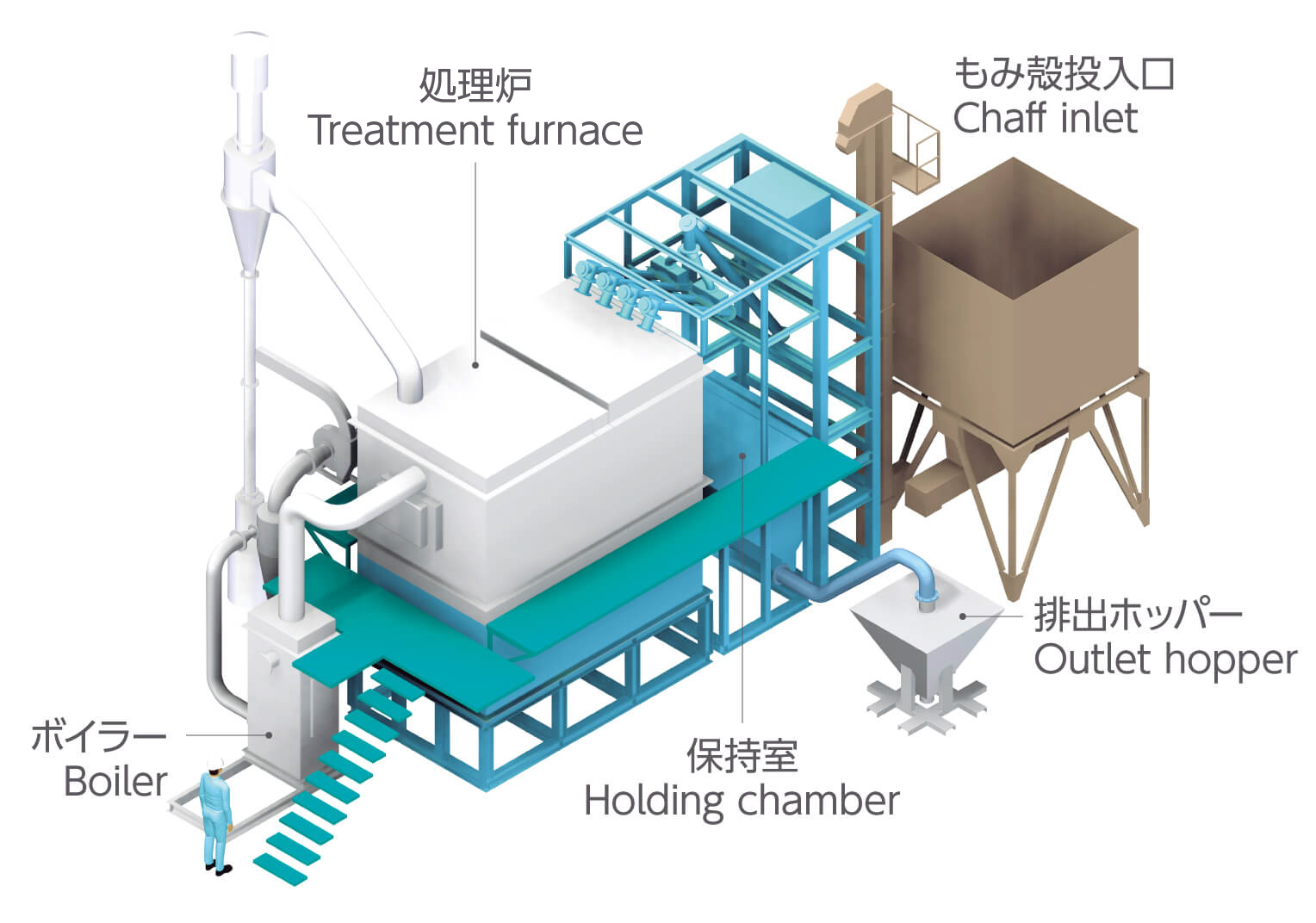

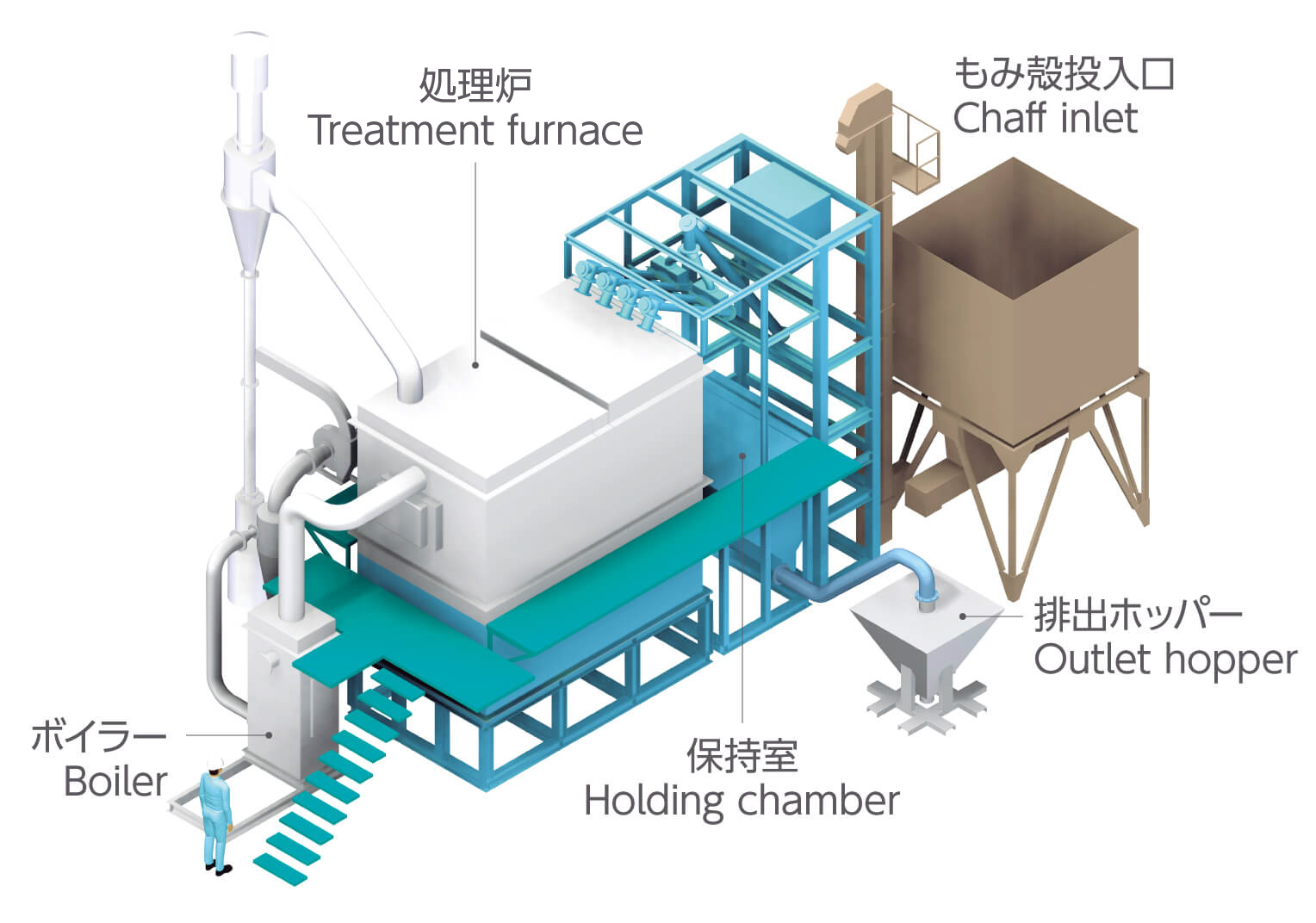

Rice husk processing furnace

The underutilized rice husks become rice husk ash, which contains beneficial amorphous soluble silica while producing heat.

Features

- High amount of heat can be obtained from rice husks, that is, dry biomass

- Heat treatment with advanced control technology, and no emission of harmful substances

- Produces rice husk ash containing beneficial amorphous soluble silica

New technology enabling safe extraction of amorphous and soluble silica

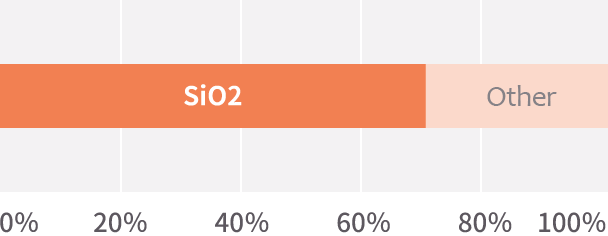

- Rice husks contain approx. 20% weight ratio of silica (SiO2 silicic acid), but if simply burned, the silica will crystallize and become less soluble in water.

- In the rice husk processing furnace, silica can be extracted from rice husks in an amorphous and highly soluble state.

- It is now possible to manufacture "rice husk silica ash" depending on the application, such as agriculture, industry, and food additives, etc.

- The rice husk processing furnace was introduced to JA-Imizuno in 2018 and has a proven record of commercial operation.

Features of rice husk-derived silica